In 2021, the founder of DSC Energy personally supported one of the leading battery manufacturers in South America with the planning and setup of their first ever lithium battery pack assembly line.

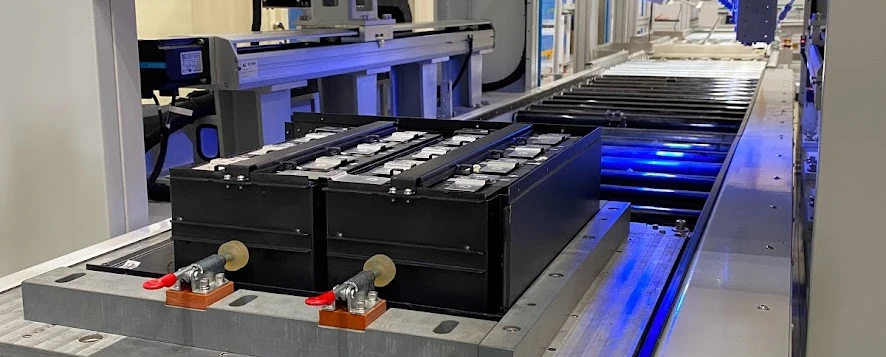

Our customer’s assembly line

Challenge

Since the customer came from a lead-acid background and had no previous experience in the lithium segment, they faced four pressing issues:

- Finding reliable battery cell and assembly component suppliers that were interested in cooperating with them.

- Evaluating which of those potential partners were most suitable for this particular project.

- Defining the process flow and sourcing the assembly and testing equipment needed for local assembly.

- Getting their factory and personnel ready for SKD assembly—incl. factory floor design, machine installation, operator training and other related tasks.

Approach

The DSC Energy founder was engaged by the customer as an external consultant for this project. With his help, they were able to find and meet several potential partners in Asia, and select the most suitable one based on strategy and planning considerations, including compliance with the customer’s specifications, as well as their manufacturing and engineering capabilities.

We helped choose the most suitable component and equipment suppliers based on the product specification

Another view of our customer’s assembly line

Solution

The CKD partner was requested to transfer not only the materials, but also the necessary know-how and technology. An agreement was signed and, after testing the samples provided by the supplier to make sure they met the customer’s requirements, the final battery specification, BOM and SOP were transferred to the customer under our supervision.

DSC organized the transfer of the necessary knowlodge and technologies from the different suppliers to the end user

Once the assembly line arrived to the customer’s premises, DSC Energy coordinated the installation and commissioning tests. After the local engineering team and operator were trained, our client was able to conduct a pilot run.